Find out more

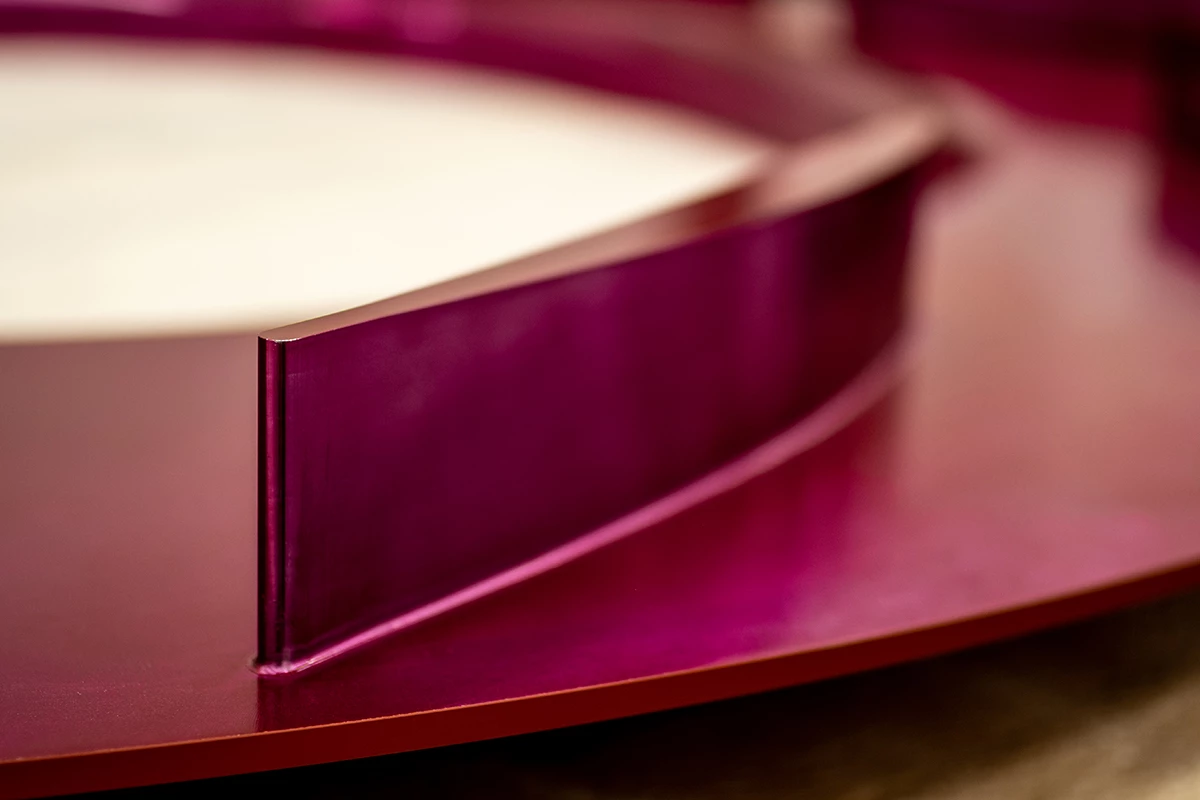

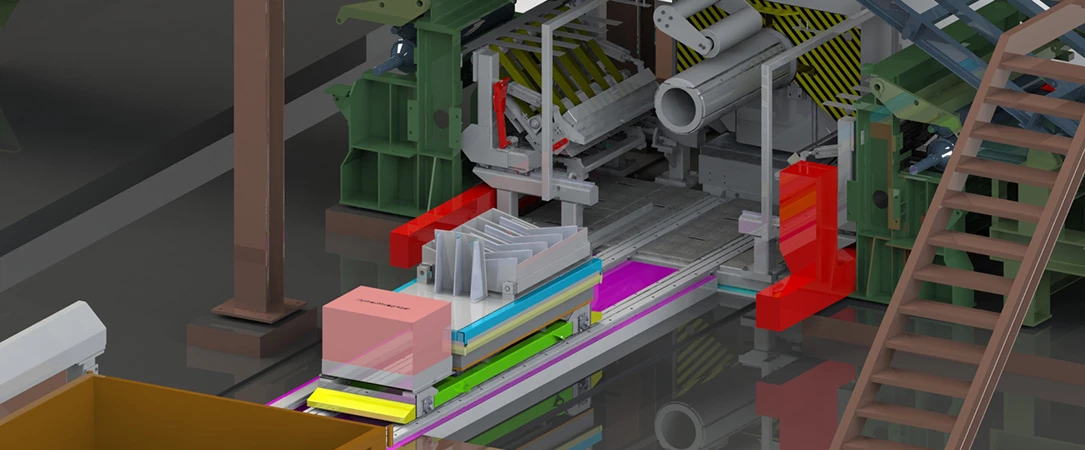

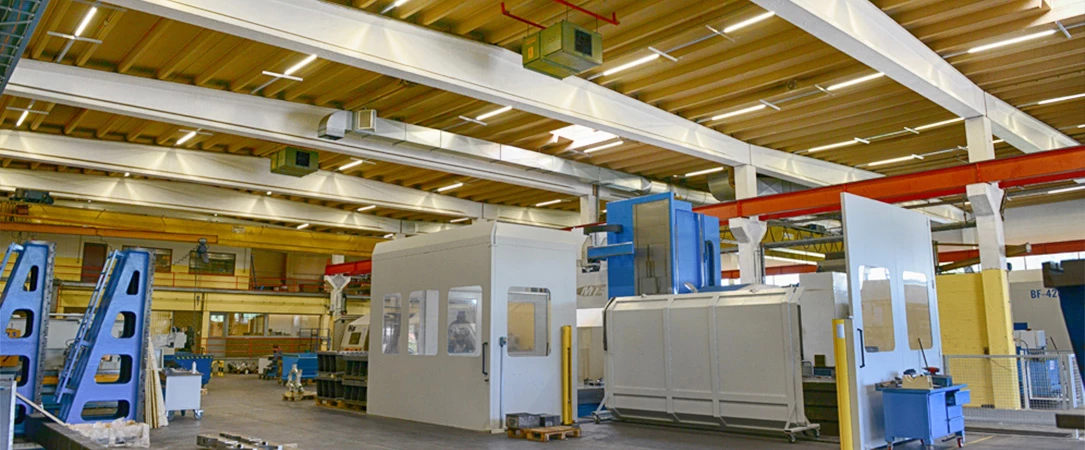

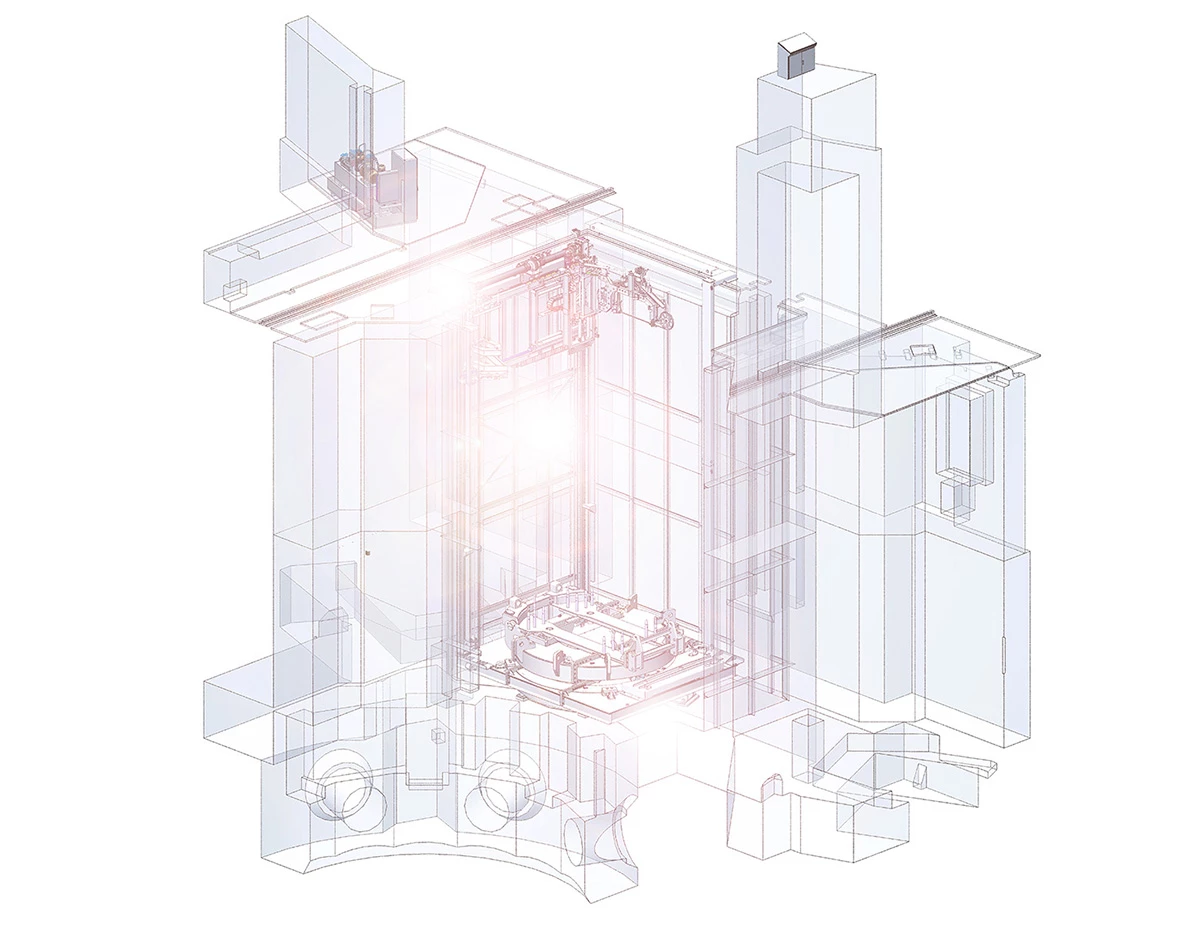

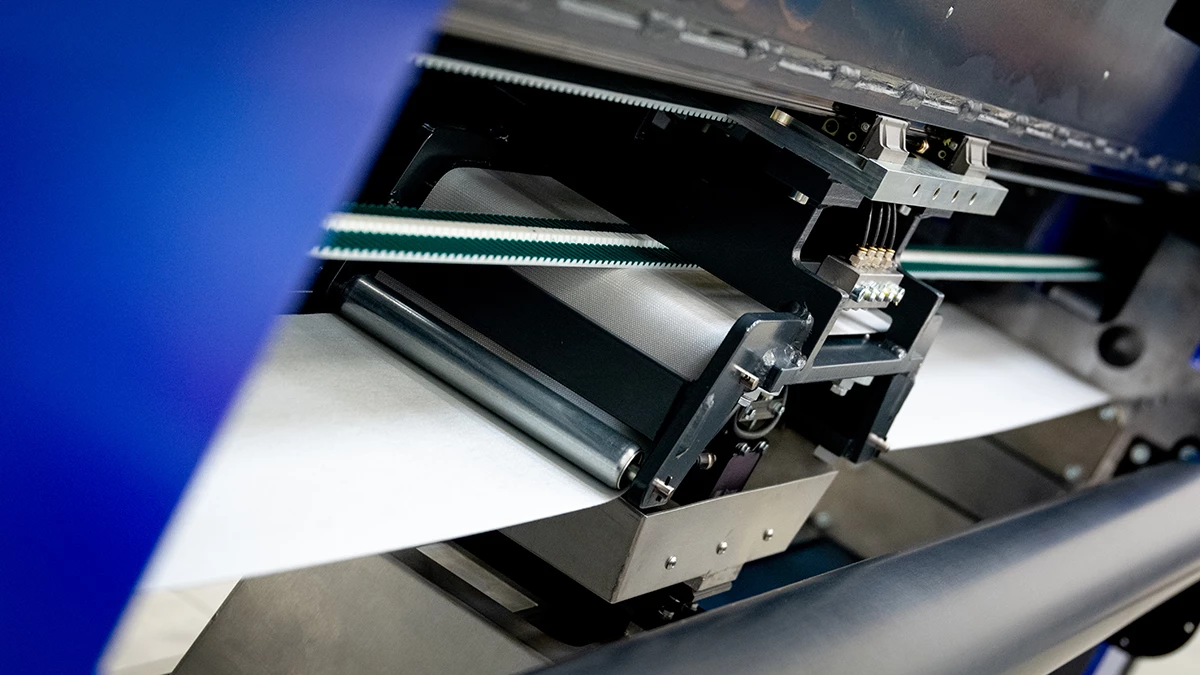

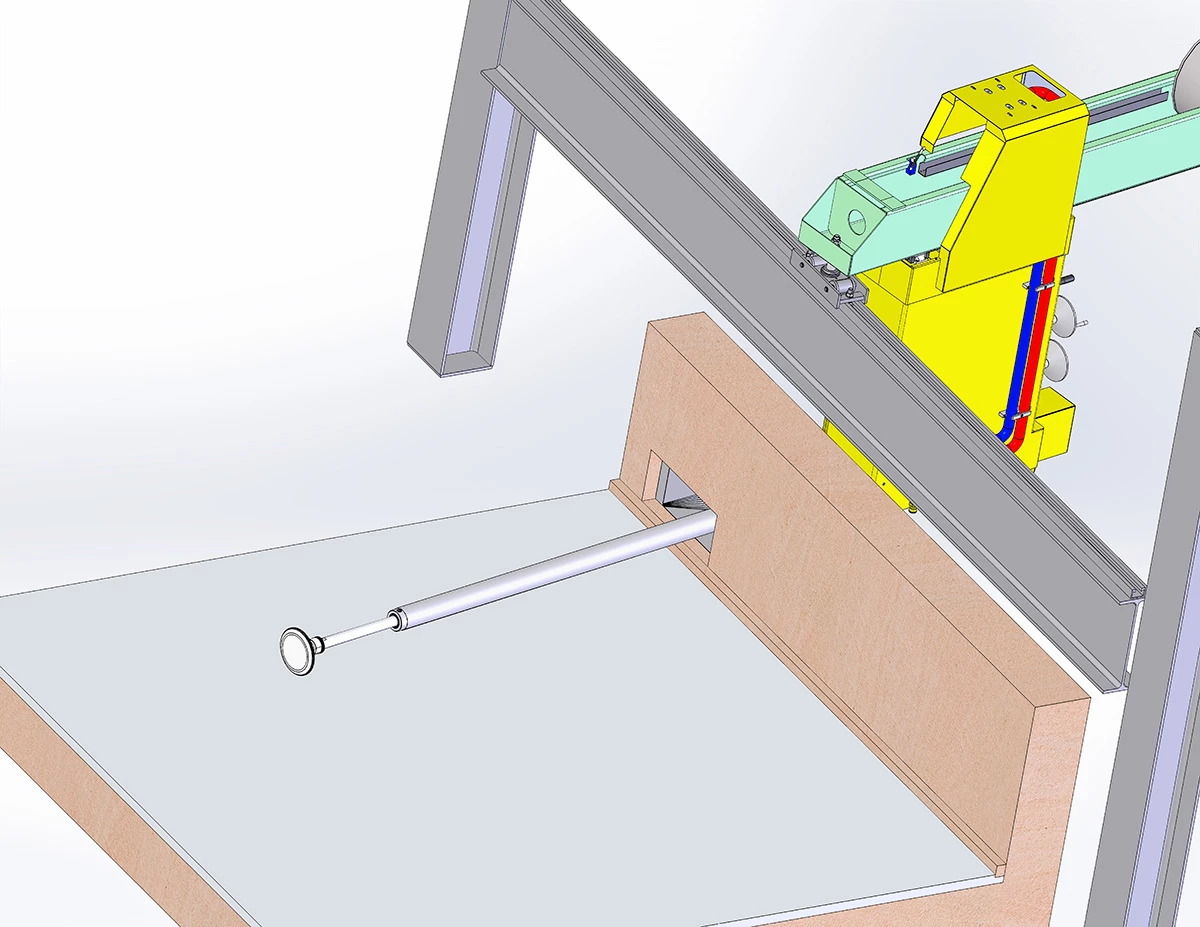

The 100th Cyclone®KIUBE from IBA has rolled out of KARL HUGO’s production workshop!

KARL HUGO, a Belgian leader in mechanical engineering, and IBA, a global leader in proton therapy, have combined their expertise to develop a revolutionary machine in nuclear medicine: the Cyclone®KIUBE, delivered worldwide. A look back at the succes...

Read More

Read More

4_bis-webp.webp)